CNC

- February 21, 2016

- Comments Off on CNC

- Thomas O'Rourke

CNC

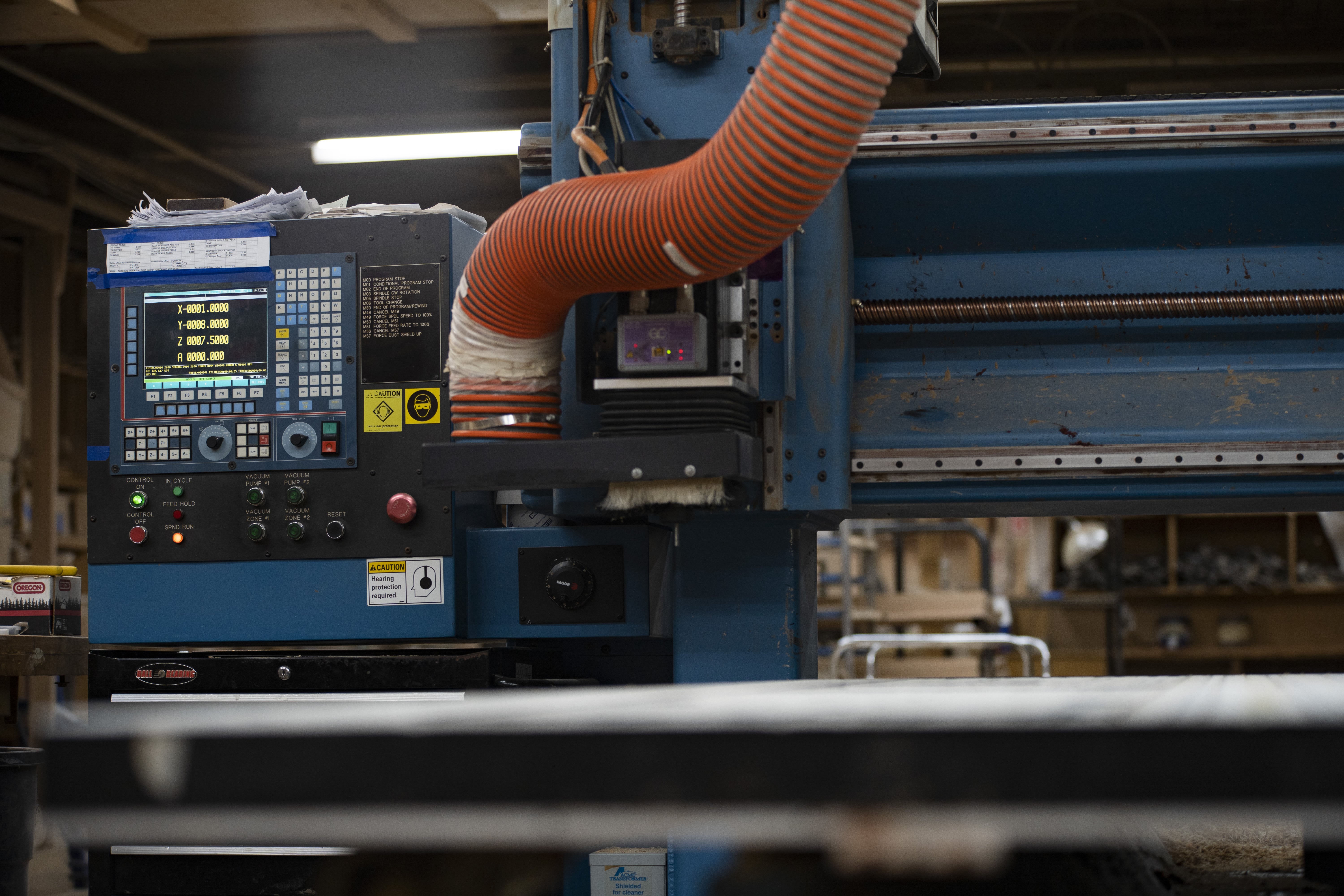

At Hardwood Design Inc, we can guarantee all of our staircases are made with precision because we use top-of-the-line Computer Numerical Control (CNC) machining in our workshop. These devices allow us to carve and route a wide array of stair parts for customers – whether they are interested in having us create and install an entire flight or would like our designers to craft a signature newel post.

This machine is a 10 horse router driven by a computer controller. With this we are able to cut and profile a wide variety of materials including solid wood and panels. The material is held in place on the machine bed by two powerful vacuum pumps so that blanks and finished pieces can be loaded and unloaded efficiently and safely. The router can be programmed to select and automatically change cutters that are stored in a rotating tool holder on the machine.

Before we actually cut into any wood, our designers create a very specific AutoCAD drawing for the machine to follow that a programmer converts to machine language using MasterCam. The accuracy of the CNC allows us to produce designs that would be impractical, if not impossible, to make by hand.

We retain all of our old drawing blocks for potential customers to browse. These illustrations offer customers design inspiration as well as hard-copy examples of our designers’ skills and expertise.

A CNC cut piece is not only higher quality than a handmade piece, but it is also less expensive and has a much shorter turnover time from order to delivery.

In addition, there are no limits to the size of a project we take on or the amount of involvement we have in putting a staircase together. If a customer comes across a specific challenge over the course of constructing their flight, we are more than happy to consult on it and use our state-of-the-art tools to help make their project come together.