Fabrication

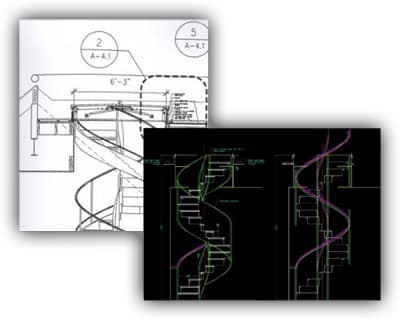

To qualify as a stairbuilder, you have to be much more than just a gifted woodworker. Our people are passionate about the trade and have the creative talent to craft projects that are thoughtful and beautiful. With hundreds of complex staircases successfully completed, we are creative problem solvers, equipped with vast experience that we can apply to unique projects that other shops wouldn’t dare undertake.

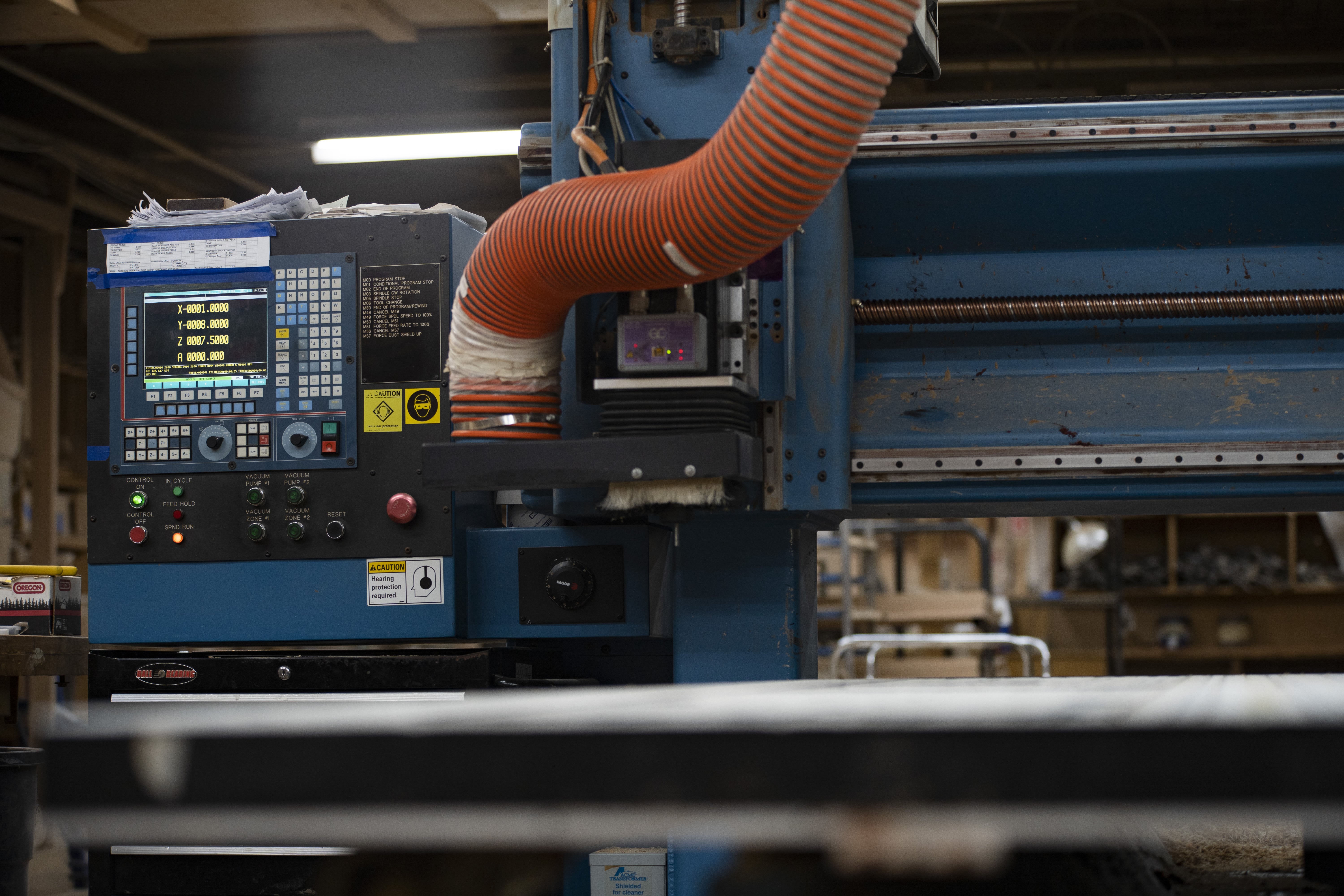

We are sized and equipped to handle several complex projects simultaneously, while other shops are too small to handle large jobs or too big to pay attention to the details of more ornate flights. Our perfectly sized 15,000 square foot workshop is divided into dedicated fabrication departments that allow our stairbuilders to focus all of their attention on each task at hand. This includes a curved stair area that has a 20-foot-tall ceiling, allowing us to form and bend curved stringers and railings.

Other departments include the straight stair shop, which has low benches to facilitate assembly and a bench room, where craftspeople use hand tools and bench vices to do all of our handwork and component assembly. We even have staging areas for incoming materials and outgoing orders, and office space for our designers, project managers and our sales and accounting departments.

We inventory a large selection of raw materials to hand select and match for each project, having established a supply chain of vendors and trade partners over the past two decades.

Quality is valued over quantity at Hardwood Design Inc. Instead of mass-producing stair parts, we put all of our efforts into the high-quality projects that our customers approach us with. Our business model can sustain itself during any economy, because our aim is to maintain our reputation as a premier stairbuilding operation that is trusted throughout the region.

What we create takes talent, tools and experience, as each piece gets our thought and attention – from a single rail fitting to a fully assembled stair. Stop by our Exeter, Rhode Island, workshop to see what we are capable of, or reach our offices by phone (401.294.2235), fax (401.295.1086) or email (info@hdistair.com).